Pompa MAPLE 60 BINKS |

Pompa do malowania, pompa do lakierowania, pompa do farb, pompa do lakieru, pompa malarska, pompa lakiernicza |

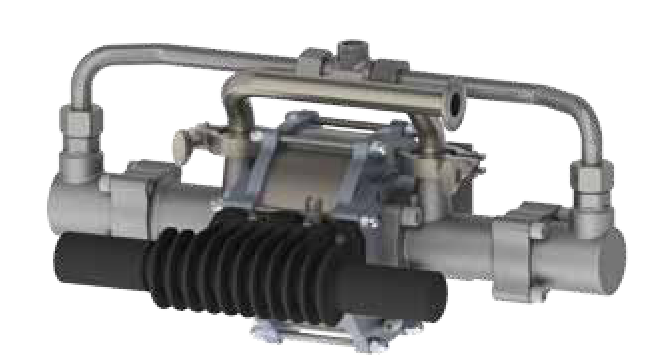

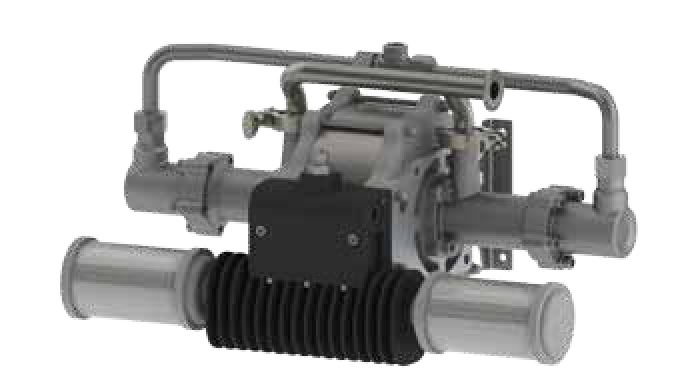

Maple ™ Pump

Low Pressure and Medium Pressure Models |

| |

|

| |

The Finishing Industry's Best Pump Solution For:

|

• High solids to CARC to UV, moisture sensitive to shear sensitivecoatings

• Reliable operation

• Simple maintenance

• Hydraulic efficiency |

| |

1 Handles the Troublesome and Difficult Coatings

• From high solids to CARC to UV.

• From moisture sensitive to shear sensitive.

• Both sides of fluid seal are flooded with fresh material.

2 Reliable Operation

• Backup seal ensures you can keep on pumping until the next shift. No need to shut down entire facility if a bellow seal fails.

• Quick exhaust valve enables rapid switchover and smooth flow.

• Quick exhaust valve herds cooling/icing away from the air logic for the industry’s most reliable motor.

• Tough construction — these pumps are made from hardened and chemically resistant materials including tungsten carbide, ceramic coated stainless steel, stainless steel, and fluoroplastic.

3 Simple to Maintain

• Inspection hose indicates when it's time to replace bellows.

• Backup seal ensures material doesn't enter air motor if bellows seal fails.

• No "upper seal" to keep lubricated or adjusted.

4 Hydraulically Efficient

• Piston seals are always engaged. If the air motor is consuming air, you're moving fluid, unlike some competitive designs. |

| |

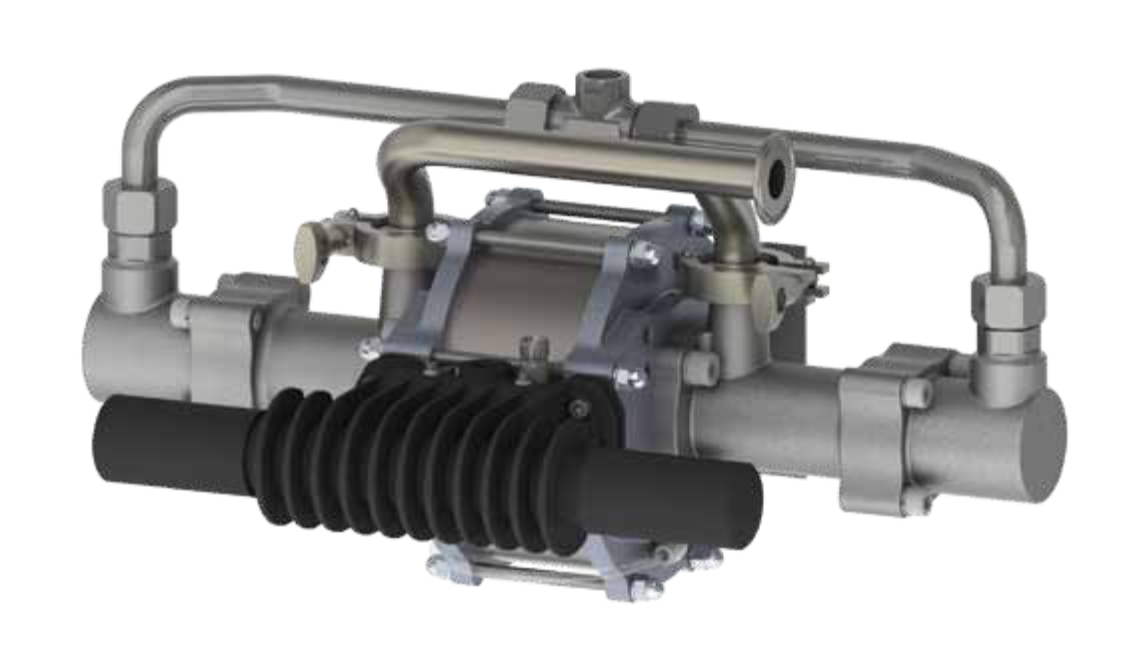

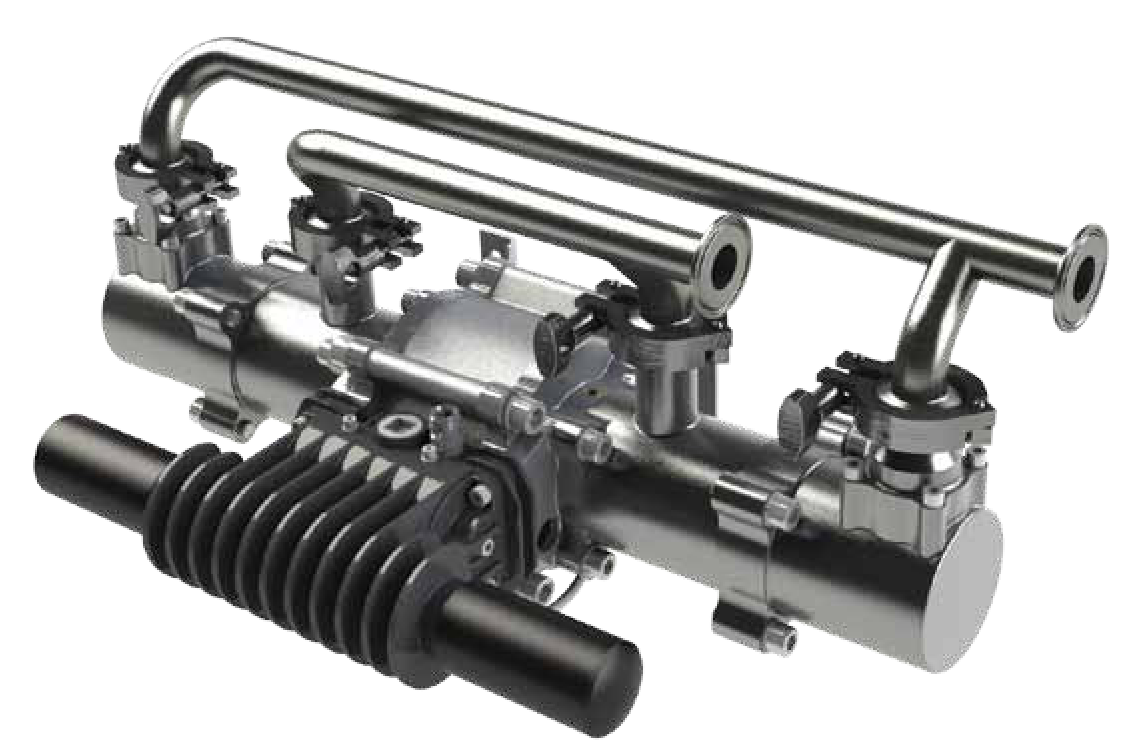

Optimized for irculation Systems or Spray Gun Feed Applications. Choice of two medium pressure models and four low pressure models. Used worldwide with the following coating systems:

• Waterborne

• High Solids

• High Abrasives

• CARC

• UV Cured

• Solventborne

• Catalyst

|

|

|

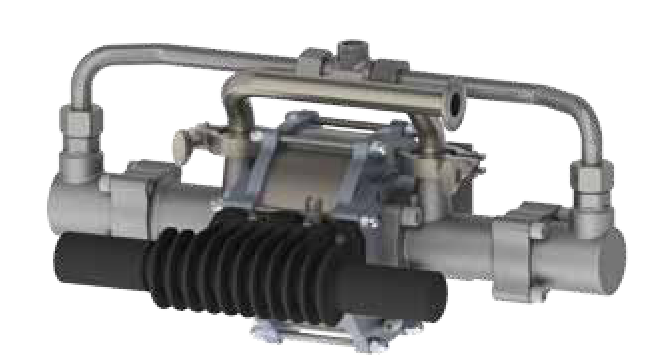

| Binks Maple 7/15 |

Binks Maple 8/25 |

|

| |

| Binks Maple™ Horizontally Opposed Piston Pump Series |

| |

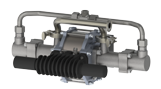

| The Finishing Industry's Best Air Motor |

| |

|

| |

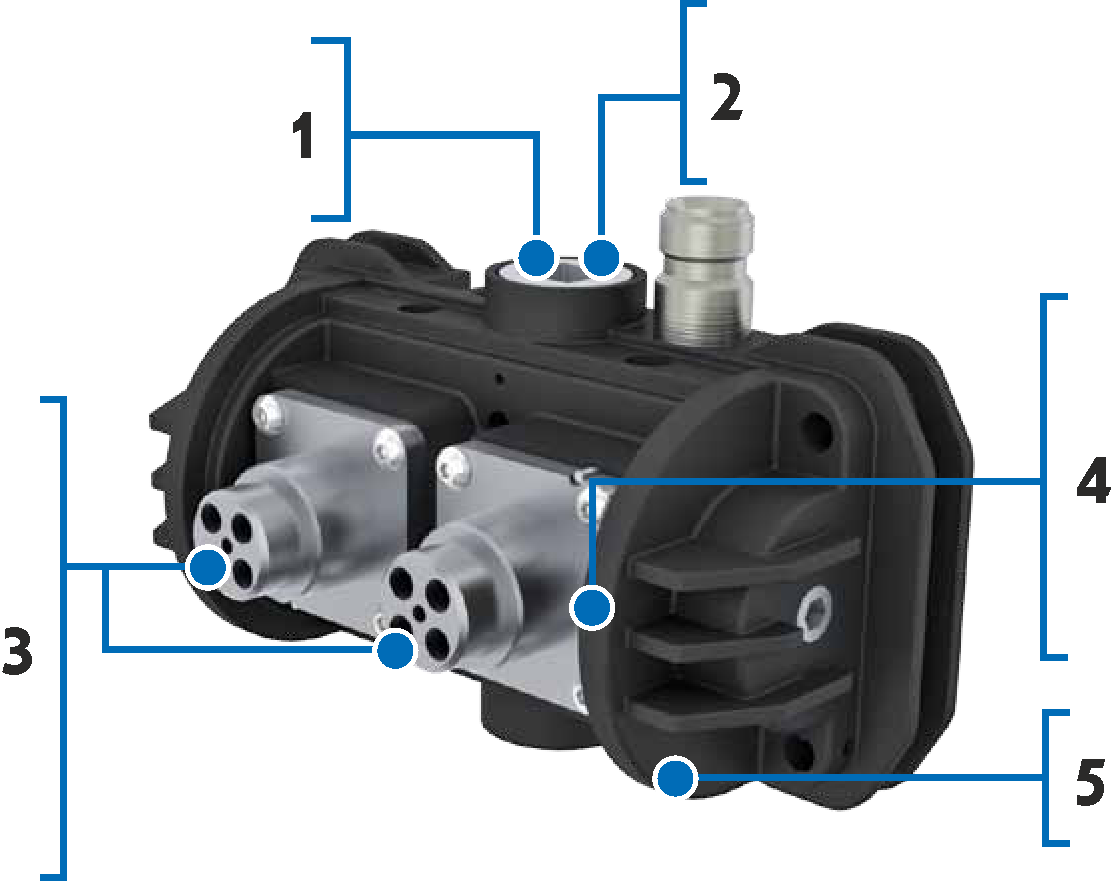

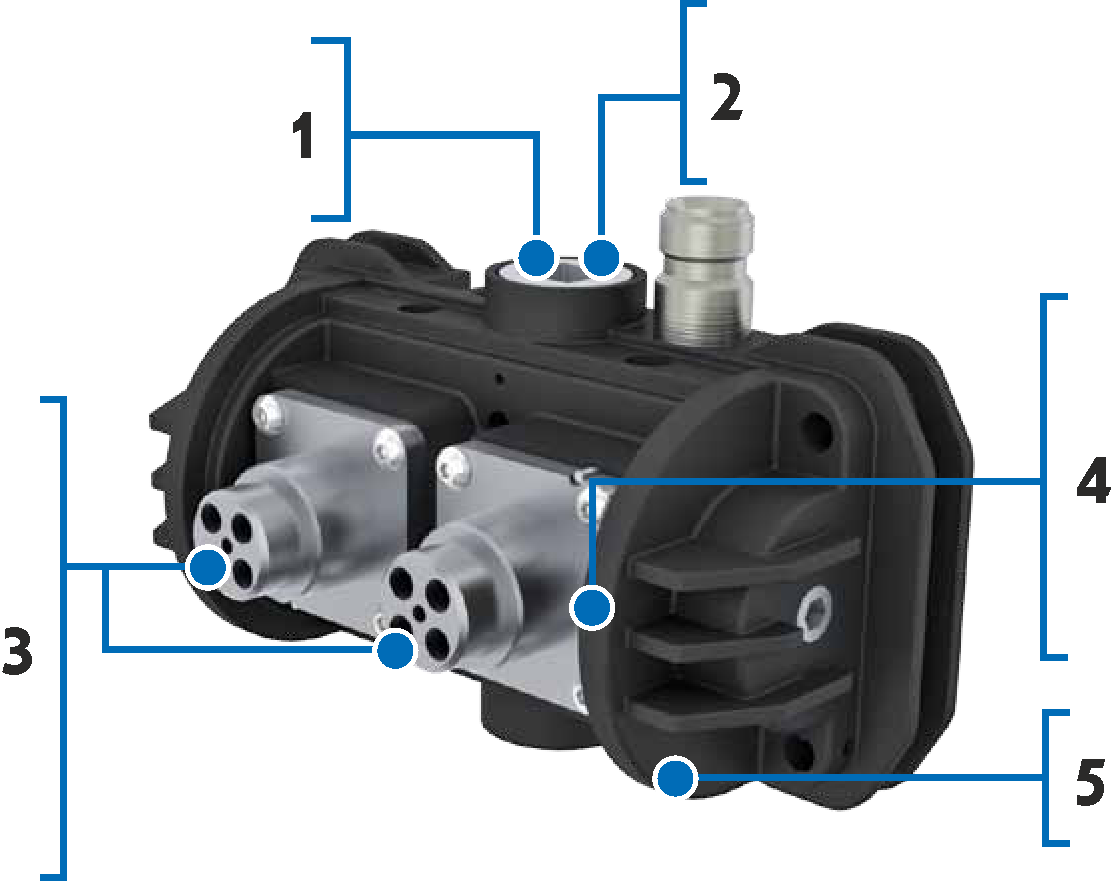

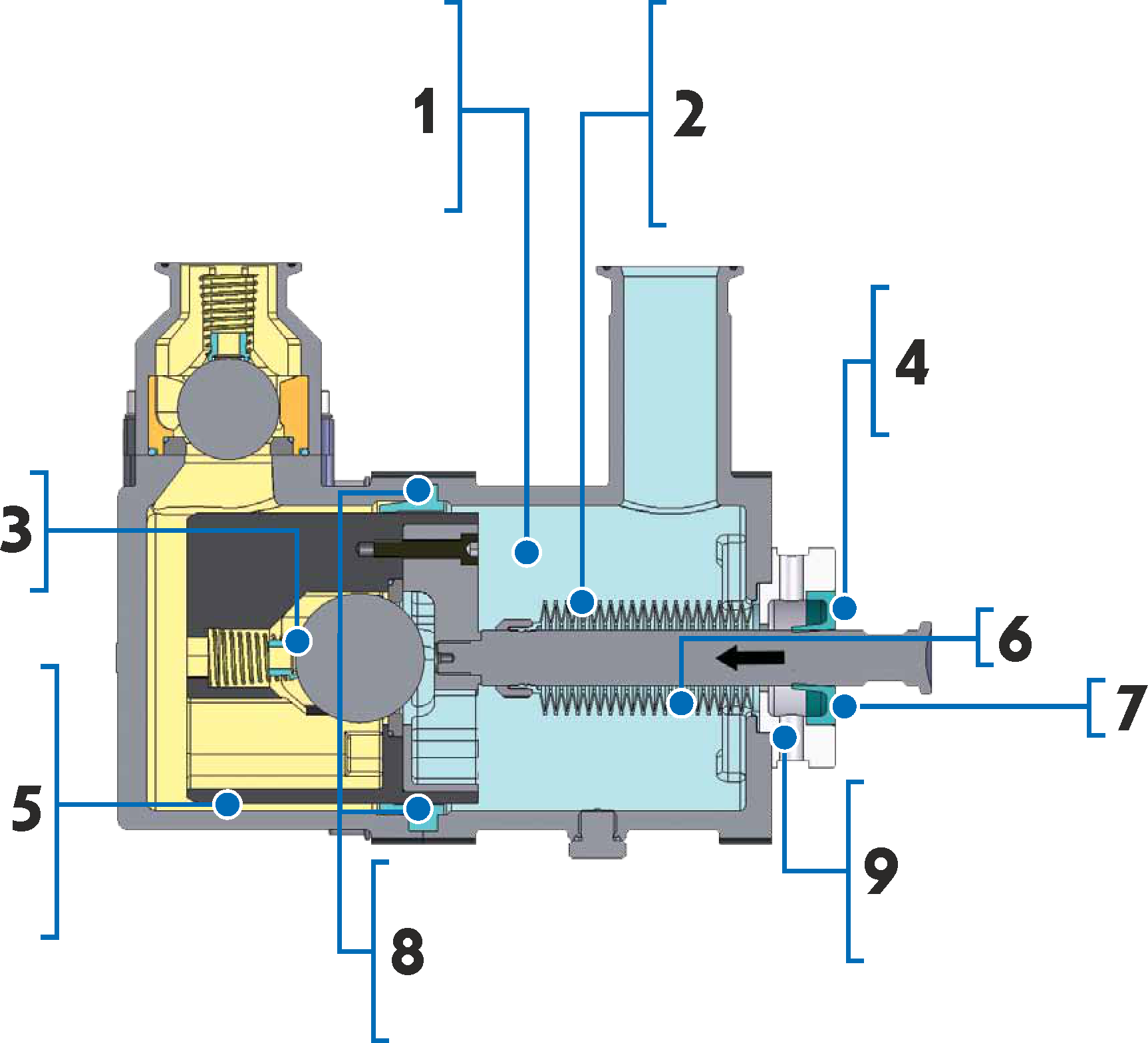

1 ● Magnetic Detent Air Logic requires less force to switch over. The result is smoother flow and lower minimum operating pressure.

2 ● Lube Free Air Logic. Lubrication + Water + Dirt = Mud. The Maple pump uses no lubricant in the air logic and requires no external lubrication.

3 ● Quick Exhaust Valve and Poppet Actuated Air Logic Gives You Two Benefits:

• If icing occurs, it is away from the air logic, virtually eliminating "stalling".

• Extremely quick switchover performance for smoother flow.

4 ● Low Ice Air Motor. The Maple pump controls where any icing happens: away from the air logic. The result is the industry’s most reliable air motor even with moist air.

5 ● Easy to Maintain. Repair air valve in 5 minutes. |

| |

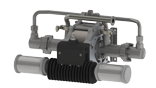

| The Finishing Industry's Best Fluid Section |

| |

|

| |

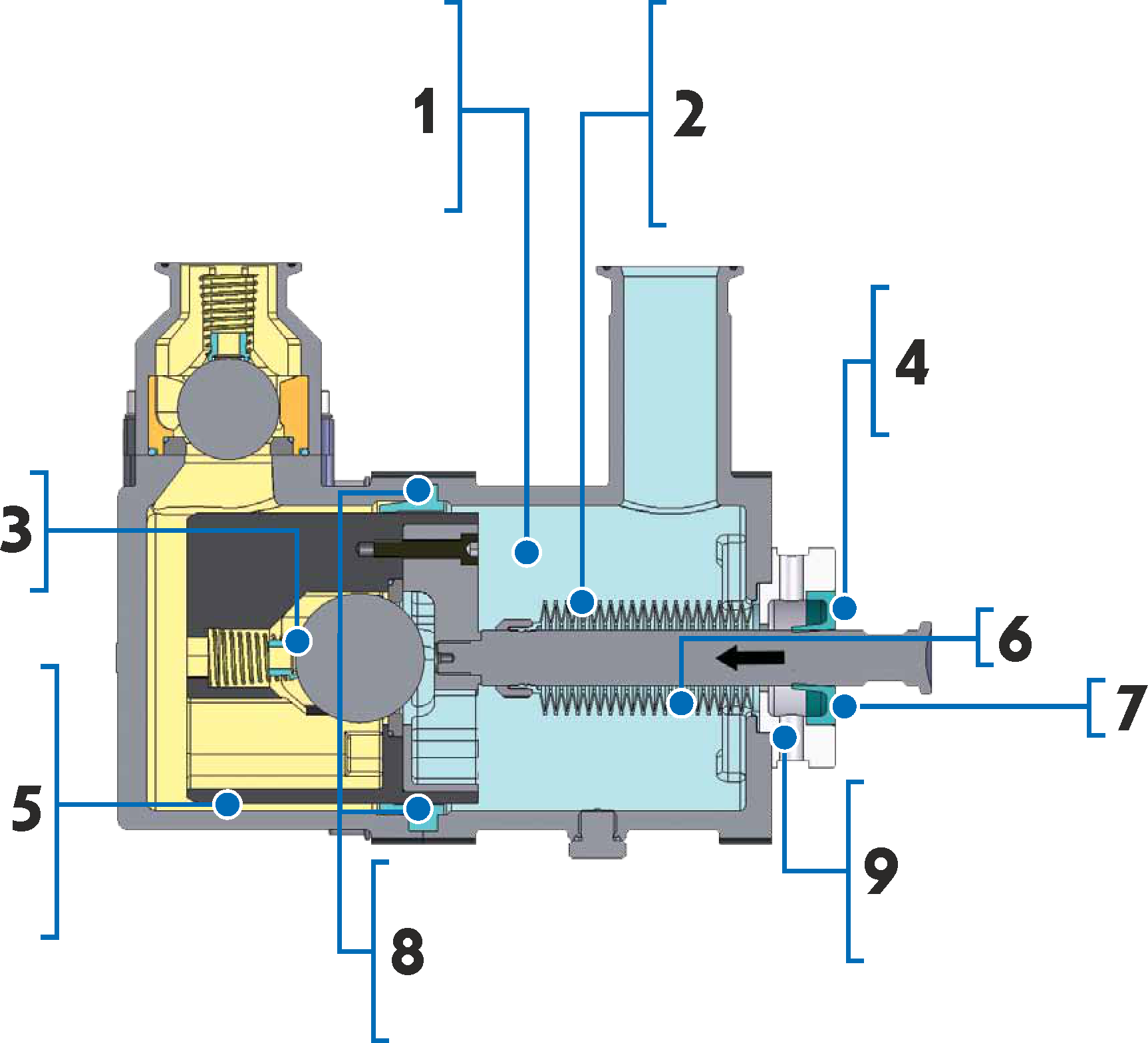

1 ● Both Sides of Seal are Flooded with Fresh Material. Troublesome materials such as UV, waterborne, moisture sensitive or shear sensitive coatings simply aren’t a problem

2 ● Binks Maple Pump "Run to Failure" Bellows System:

• Has moren convolutions than competition to minimize stresses and increase life.

• Is made of fluoroplastic with chemical resistance properties similar to PTFE.

3 ● Lower Ball Check in fluid piston.

4 ● Back Up U-Cup Seal. When the bellows wear out, you won’t contaminate the air motor!

5 ● Ceramic Pistons and Tungsten Carbide Seats give you the industry’s best maintenance cycle.

6 ● Bellows

7 ● Backup Seal

8 ● Seal is Always Engaged so you’re always moving fluid. You’ll consume significantly less air than you would if using a competitive design.

9 ● Visual Inspection Hose attaches here. When you see material here, it’s time to change the bellows. But you can keep on pumping until the next shift! |

| |

| Binks Maple™ |

| |

| |

|

|

|

|

|

|

| ORDERING Information |

MAPLE 15 |

MAPLE 30 |

MAPLE 60 |

MAPLE 20 AFP* |

MAPLE 7/15 |

MAPLE 8/25 |

| PART # |

104009-N |

104010-N |

104020 |

104016 |

104041-N |

104042-N |

| Weight |

46 lbs (21 kg) |

66 lbs (30 kg) |

145 lbs (66 kg) |

77 lbs (35 kg) |

57 lbs (26 kg) |

88 lbs (40 kg) |

| Ratio |

3:1 |

3:1 |

3:1 |

4.2:1 |

15:1 |

25:1 |

| Flow @ 60 Cycles/Min |

6 gal(23 liters) |

12 gal(45 liters) |

24 gal(91 liters) |

6.8 gal(26 liters) |

2.6 gal(10 liters) |

3.2 gal (12 liters) |

| Displacement/Cycle |

375 cc/0.1 gal |

750 cc/ 0.2 gal |

1,500 cc/0.4 gal |

475 cc/0.125 gal |

166 cc/0.044 gal |

200 cc/.053 gal |

| Inlet Fluid Connection |

1" Sanitary |

1 ½" Sanitary |

1 ½" Sanitary |

1" Sanitary |

1" Sanitary |

1" Sanitary |

| Outlet Fluid Connection |

1" Sanitary |

1 ½" Sanitary |

1 ½" Sanitary |

¾" Sanitary |

½" NPT Female |

½" NPT Female |

| Air Connection Wetted Materials |

3/8 NPS (m)/BSP (m) |

3/8 NPS (m)/BSP (m) |

3/8 NPS (m)/BSP (m) |

3/8 NPS (m)/BSP (m) |

3/8 NPS (m)/BSP (m) |

3/8 NPS (m)/BSP (m) |

| Max Fluid Pressure |

300 psi (21 bar) |

300 psi (21 bar) |

300 psi (21 bar) |

420 psi(29 bar) |

1,575 psi (109 bar) |

2,625 psi(181 bar) |

| Air Consumption@ 45 psi |

0.17 scfm/cycle |

0.33 scfm/cycle |

0.75 scfm/cycle |

0.33 scfm/cycle |

0.33 scfm/cycle |

0.7 scfm/cycle |

| Max Air Inlet Pressure |

100 psi (6.9 bar) |

100 psi (6.9 bar) |

100 psi (6.9 bar) |

100 psi (6.9 bar) |

100 psi (6.9 bar) |

100 psi (6.9 bar) |

| Max Recommended Continuous Cycle Rate |

20 cpm |

20 cpm |

20 cpm |

20 cpm |

20 cpm |

20 cpm |

| Instruction Manual Part # |

104009 |

104010 |

104020 |

104016 |

104041 |

104042 |

|

| |

| *For use with piggable systems with push and solvent air chop. |

| |

| PART # |

Accessories |

| 41-28283 |

100 Mesh Filter Kit Top Mount |

| 41-28284 |

100 Mesh Filter Kit Rear Mount |

| 104050P-B-B |

2" Sanitary Active Surge Eliminator |

| 104050P-C-C |

1 ½" Sanitary Active Surge Eliminator |

| 104050P-D-D |

1 ½" NPT (Female) Active Surge Eliminator |

| 104050P-L-L |

1" Sanitary Active Surge Eliminator |

| 104053-C-C |

1 ½" Sanitary Surge Chamber |

| 104053-D-D |

1 ½" NPT (Female) Surge Chamber |

| 104053-L-L |

1" Sanitary Surge Chamber |

|

| |

|

| |

| Part # |

Accessories |

| 107750 |

Low Shear Back Pressure Regulator, ¾" Ports, Stainless Steel, No Gauge |

| 202-55-2 |

1.5 HP Heavy Duty Agitator, 55 Gal Cover, 2 Paddles |

| 202-55-4 |

1.5 HP Heavy Duty Agitator, 55 Gal Cover, 4 Paddles |

| 106946 |

Electric Agitator - AC Inverter |

| Connection Kits for Pumps: |

| 502716 |

1 ½" Sanitary x 1" NPT (F) (2 Sets of Parts) |

| 502717 |

1" Sanitary X ¾" NPT (F) (2 Sets of Parts) |

| 502744 |

1" Sanitary X ¾" NPT (F) (1 Set of Parts) |

| 502745 |

1 ½" Sanitary X 1" NPT (F) (1 Set of Parts) |

| 41-28282 |

1" Sanitary x 1" NPT (F) (1 Set of Parts) |

|

| |

|

| |

| |

| |

| |