Pompa pneumatyczna MAPLE 15 BINKS. Pompa do lakieru, pompa do farby. |

Pompa do lakieru, pompa do lakierowania, pompa lakiernicza, pompa do farb, pompa do malowania, pompa malarska |

| |

|

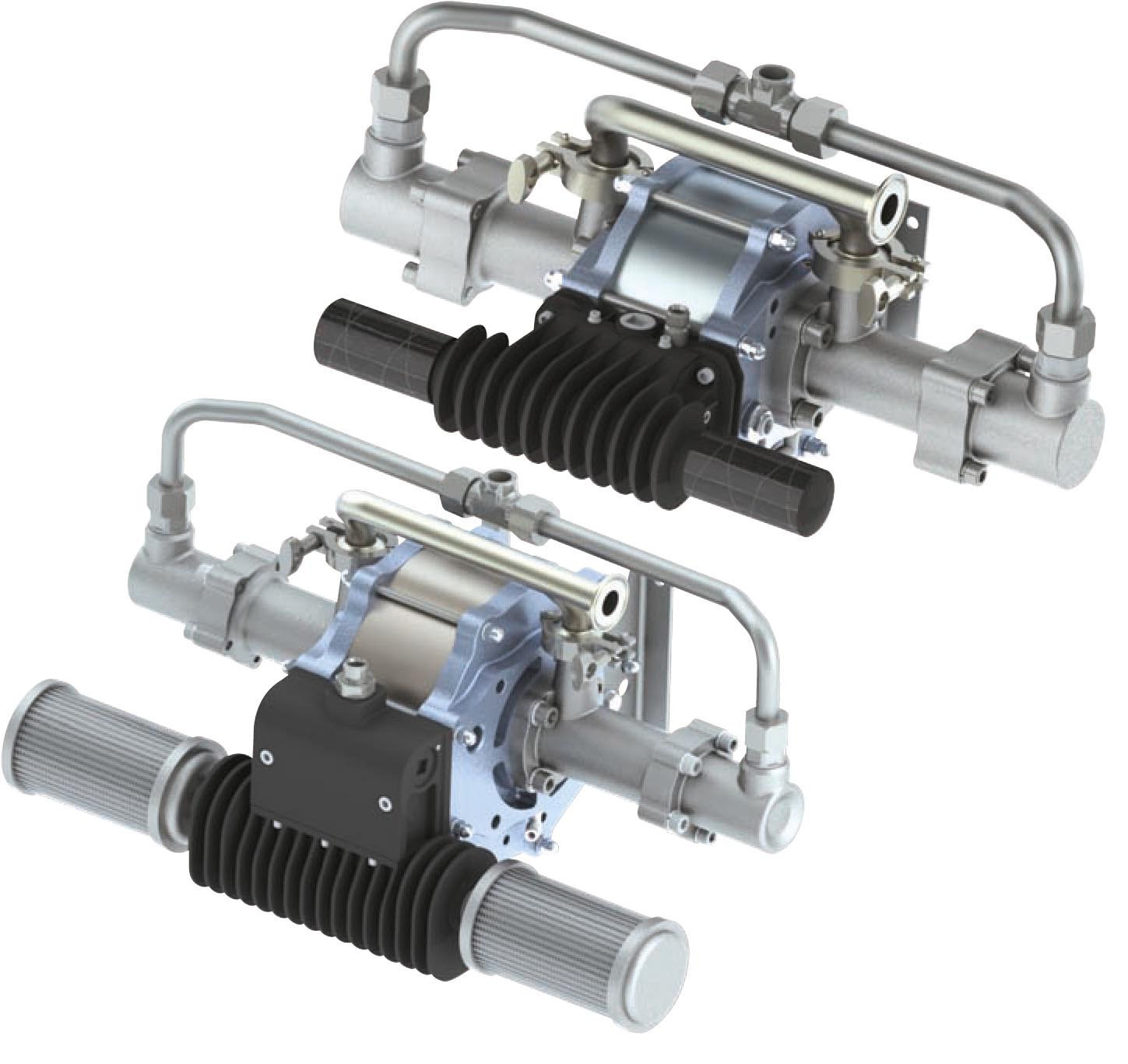

Pompa Pneumatyczna Maple 15/3 |

| |

Pompa pneumatyczna Maple to pozioma pompa tłokowa pompująca farby rozpuszczalnikowe, wodorozcieńczalne, rozpuszczalniki oraz inne stosowne materiały. |

| |

Jednostka łączy w sobie energooszczędny silnik pneumatyczny wraz z technologią niskiego ścinania płynów od gamy pomp elektrycznych Smart. Pompa Maple generuje ruch posuwisto- zwrotny przy użyciu zaawansowanej technologii szlifowanych suwaków i tulei zaworów powietrznych, które sterują odwracaniem kierunku tworząc wspominany ruch posuwisto-zwrotny. Opatentowana konstrukcja zaworu powietrznego wykorzystuje zapadki magnetyczne dla głównych zaworów powietrznych sprawiając, iż nie ma możliwości samoistnego zatrzymania się silnika. Silnik pneumatyczny wykorzystuje również opatentowaną technologię szybkiego odpowietrzania Binks – mała ilość lodu, która zapobiega wystąpieniu warunków powodujących zamarznięcie zaworu w przypadku stosowania dużych prędkości cykli. Równy nacisk na każdy skok ze względu na poziomą konfgurację i podwójny trzon tłokowy zapewniają zrównoważone ciśnienie wylotowe cieczy i zmniejszają wahania ciśnienia cieczy do absolutnego minimum. Pompa ma dwa tłumiki wylotowe ograniczające hałas do minimum. Zestaw adaptera ułatwia połączenie z oddalonym układem wydechowym (w razie potrzeby). |

| |

Rynki i zastosowania:

• Tłoczenie materiału w technologii Air Assisted Airless oraz Airless

• Liniowe maszyny do obróbki wykończeniowej drewna

• Obrotowe maszyny do obróbki wykończeniowej

• Większość typów maszyn do automatycznego natryskiwania

• Tłoczenie do wielu pistoletów i do pistoletu automatycznego

• Układy obiegowe Typowe materiały i rodzaje powłok:

• Materiały wrażliwe na wilgoć

• Materiały rozpuszczalnikowe i wodorozpuszczalne

• Powłoki natryskowe katalizowane

• Bejce, pokosty i lakiery

• Impregnaty i powłoki gruntowe

• Powłoki o dużej zawartości cząstek stałych

• Materiały ścierne |

| |

Specyfikacja POMPY MAPLE BINKS Pneumatycznej pompa Maple 15/3 |

| |

| Nr części |

104009 |

Zalecana maksymalna liczba:

cykli przy pracy ciągłej

cykli przy pracy przerywanej |

20 cykli/min (7.5lpm)

40 cykli/min (15lpm) |

| Objętość materiału/cykl |

0.10 US Gal/0.375 L |

| Przepływ równoważny przy 60cyklach/min |

6 US Gal/22.5 L |

| Objętość powietrza/cykl |

0.17scfm (4.8L/m) @ 45 psi (3.1 Bar) |

| Objętość powietrza/cykl |

0.33scfm (9.3L/m) @ 90 psi (6.2 Bar) |

| 15 cykli/min |

5scfm (142L/m) @ 90 psi (6.2 Bar) |

| 30 cykli/min |

10scfm (283L/m) @ 90 psi (6.2 Bar) |

| Przełożenie |

3:1 |

| Ciśnienie powietrza na wlocie |

6 Bar / 90 psi |

| Rozmiar wlotu powietrza |

3/8” BSP/NPS |

| Złącze na wlocie/wylocie |

1” sanitarne |

| Waga |

46lbs/21kg |

| |

| Akcesoria |

| 192006 |

Uszczelka sanitarna 1” |

| 192009 |

Zacisk sanitarny 1” |

| 192779 |

Adapter do rurki wylotowej (1” NB) |

| 192803 |

Korek do rozgałęźnika 1” |

|

| |

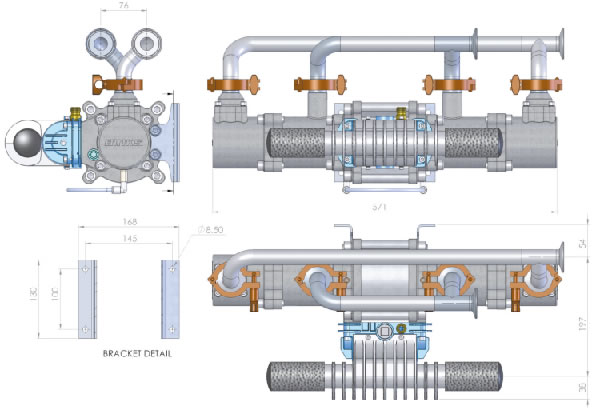

| Szczegóły połączenia zdalnego odpowietrzania prezentujące adapter rury oraz gniazdo. |

| |

| Tłoki pomp Binks Maple mają powłokę ceramiczną – najtrwalszą ze wszystkich dostępnych. Są odporne na ścieranie przez wysoce ścierne ciecze, a jednocześnie zmniejszają tarcie i wydłużają okres eksploatacji uszczelnienia pompy. Powłoka ceramiczna Binks to najlepszy wybór dla części ślizgowych w pompach. Więcej informacji na temat zalet i korzyści związanych z powłoką ceramiczną Binks jest dostępnych na żądanie. |

| |

|

Szczegóły połączenia zdalnego odpowietrzania prezentujące adapter rury oraz gniazdo.

|

| |

|

| |

|

| |

| |

| |

| |